Around the world, around the clock:

building resilience

in international supply chains.

Sustainability Pillars

Building resilience is not just about supplier redundancy and diversification. Long-term resilience includes choosing products that are safe for people, safe for the environment, affordable and accessible for customers and businesses. Concerns about excessive waste, ever-changing single-use packaging legislation, and your company’s environmental footprint are all important considerations in corporate risk-mitigation strategies. At Current, we use the triple bottom line to guide our decision making, delivering truly sustainable products for future-proof businesses:

People

Improve the well being of all consumers, workers, and communities your products touch, and adhere to the world’s highest health and safety standards.

Planet

Minimize the environmental footprint of your packaging, and strive to regenerate natural ecosystems. Eliminate waste by all means possible and enable a circular economy.

Prosperity

Use solutions that minimize cost to consumers, businesses, and society as a whole, and deliver maximum value in a way that is resilient and accessible for all.

Reduce. Reuse. Recycle. Recover.

1. Reduce material use.

The first and most obvious choice, use less! Removing unnecessary packaging and reducing weight by down-gauging is often the easiest way to lower your footprint and your bottom line. Contact us to learn how we save brands millions by optimizing designs and eliminating waste.

2. Reuse products whenever feasible.

Reusable packaging has a huge opportunity to reduce waste while bringing maximum value to consumers. While practical applications can be limited, reusable cups, bags, and cutlery are by far the most sustainable options available. Whether organic cotton tote bags, stainless steel, ceramic, or glass mugs and tumblers, Current can upgrade your brand to the most premium reusable packaging without breaking the bank.

3. Use recycled content & design for recyclability.

Recycling is the optimal end-of-life stage for any material, and improving both recycling rates and use of post-consumer recycled material is critical to building a circular economy for packaging. At Current, we have the ability to use high-quality PCR resins safe for food contact in the majority of our products.

4. Recover waste as a resource.

Most materials must be disposed of eventually. With 50% of global plastic waste being sent to landfills, 23% mismanaged and littered, and 19% incinerated, designing packaging with these scenarios in mind is essential if we want to make any significant change in our lifetimes.

Recovery happens in 3 main ways:

- Renewable natural gas capture in sustainable landfills (like those operated by Archaea Energy)

- Waste to energy facilities (incinerators)

- Material recovery through composting and biodegradation

At Current, we provide a full range of the latest biodegradable and compostable materials, including our in-house brand “Recur Perishable Plastics”. Contact us to learn how all single-use plastics can be transformed into “Perishable Plastics” with no change in performance or appearance, at significantly less cost than all other plastic alternatives.

Current's brand of

biodegradable modified

single-use plastics.

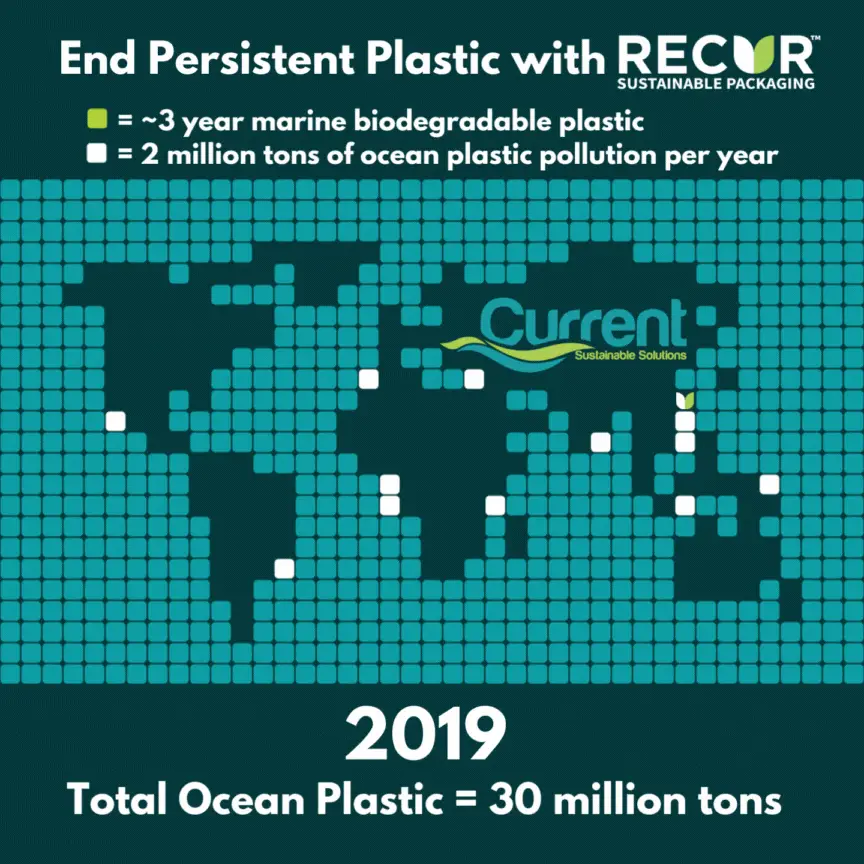

Using BioSphere biodegradable plastic technology, Recur Perishable Plastics are conventional plastics modified to become landfill and ocean biodegradable. This solves the main problem of single-use plastics: their persistence in the environment after use, while maintaining recyclability, appearance, and functionality. Through a completely biological degradation process, Recur products do not require physical breakdown to biodegrade and do not create microplastics like oxo-degradable plastics. When disposed of in landfills (the most common waste disposal method worldwide), Recur products help reduce landfill volume quickly, and can contribute to a circular economy for plastics through renewable natural gas capture. Contact us to learn how Recur Perishable Plastics can be used with your products today.

Commonly Recyclable

Recyclable alongside conventional plastics, unlike compostable plastic alternatives.

Biologically Recoverable

Independently certified to biodegrade in landfills and ocean environments in a matter of years, not centuries.

Practical & Economical

No change in product properties, with minimal price impact, significantly cheaper than compostable plastic alternatives.

Enables Circular Plastics

Contributes to a circular economy for plastics through renewable natural gas capture in sustainable landfills.

Why Recur?

Landfills around the world are filling up.

Globally 72% of plastic waste is either sent to landfills or informally discarded in the open environment. These most unfortunate end-of-life scenarios are the heart of the plastic problem that Recur seeks to address.

With Recur, plastic waste can be recovered and used again as a resource in two main ways: Renewable Natural Gas capture in landfills and biological recovery by nature in the open environment, in a much shorter time frame compared to conventional plastics.

From the OECD Global Plastics Outlook, it is clear to see that plastics are far from circular and an enormous amount is being leaked into the environment. With this high level understanding, we can begin to design solutions that will have maximum impact, using the world’s existing supply chains, consumer behaviors, and waste management infrastructure.

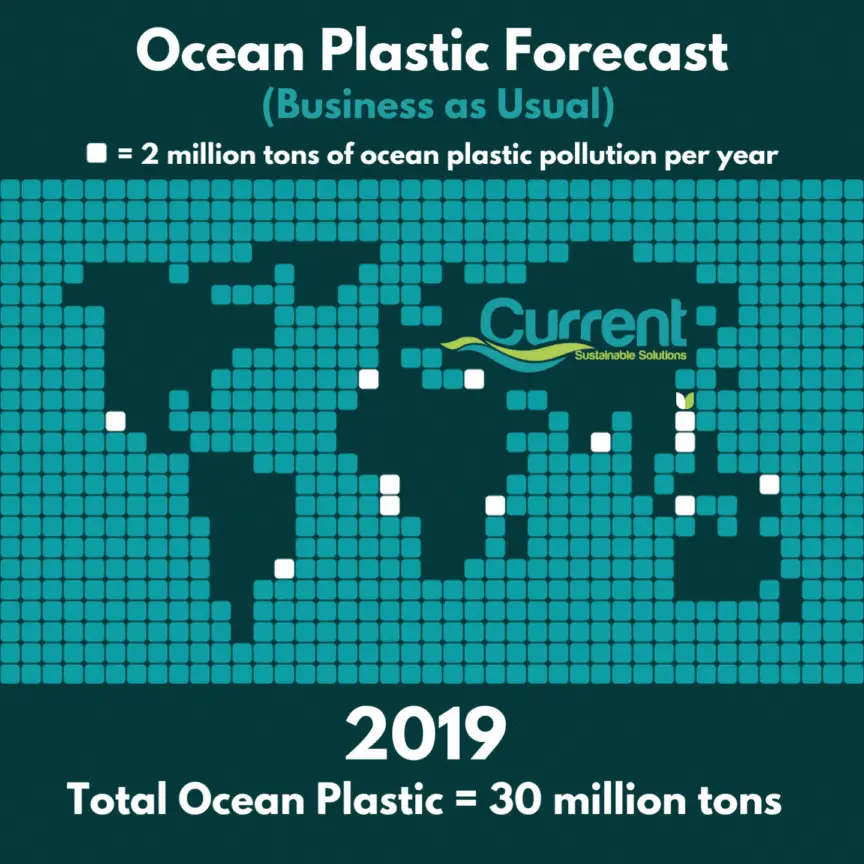

2 million tons of plastic enters oceans every year.

According to the OECD Global Plastics Outlook, plastic leakage to the oceans was 1.7 million tons in 2019. Other sources estimate it could be up to 11 million tons per year. With plastic use on the rise, the below estimate of 300 million tons by 2154 is very conservative. That’s 1 gram for every square meter of ocean, if we can still call it that.

While only about 0.5% of plastic produced each year escapes into the ocean, this is by far the worst possible end-of-life scenario. As the last line of defense in plastic pollution, Recur Perishable Plastics will never become persistent pollutants in the oceans or open environment.

Bioplastics are expensive and not scalable.

While bioplastics avoid using fossil fuels, they do require agricultural land and resources to produce, creating whole new categories of environmental impact such as terrestrial acidification, eutrophication, and ozone depletion from fertilizer use.

Bioplastic production capacity is still only about 1% of fossil fuel-based plastic production capacity, so affordability and accessibility will be major constraints for the foreseeable future.

The most common biodegradable bioplastic, PLA, requires a high-temperature industrial composting facility to completely biodegrade. These facilities are not common in most of the world. Industrial composting facilities are designed to compost food and agricultural waste, and many refuse to accept bioplastics since they reduce the quality of their compost.

While technically recyclable, bioplastics like PLA will not be recycled if placed in the recycling bin. This is a major downside when trying to build a circular economy for plastics. Material recovery facilities are not yet equipped to identify and separate bioplastics from conventional plastics, meaning they will likely end up in a landfill or incinerator.

By working within the constraints of our existing global infrastructure, Recur Perishable Plastics have the most potential for an affordable, scalable, and immediate impact on the sustainability of single-use plastics.

Products in development.

Various films in development, including:

• CPP / OPP / BOPP

• Lamination Films

• LDPE / LLDPE / HDPE

For packaging, medical, & personal care industries:

• PP spun-bond fabric

• Option of 30% CaCo3 for reduced virgin plastic

For cups, trays, lids, containers, and rigid packaging:

• PP & PET

• PSM (Plant Starch Material)

Follow us as we develop, test, & certify a complete line of sustainable single-use plastics.

Contact us to learn how you can use Recur Perishable Plastics today.

The last line of defense against plastic pollution.

Sustainable Packaging FAQ

While we sell single-use packaging of all materials, our priority and first recommendation to brands is to start by using less of it, no matter the material. We aid this through strategies like down-gauging, design optimization, and improving stack-ability for more efficient shipping. All are primary ways to reduce cost, and just make sense as a part of good design.

Sustainable is one of those words that has been overused to the point of becoming meaningless.

There are many ways to evaluate a packaging material’s environmental sustainability. The best way is to compare the LCA of each, which includes:

The total energy and water used to extract or grow the natural resource and process it into a usable product

The degree of impact the extraction, production, distribution, use, and end of life disposal scenario has on the natural environment

The ability of the material to be either recovered for recycled content or for energy after it’s useful life

In addition, we evaluate packaging’s social sustainability by looking at:

- Any potential toxicity

- The social working conditions along the product’s full lifecycle, from resource extraction to disposal

The performance properties of the material, and it’s ability to package goods safely and hygienically

And finally for the most quantifiable metric, economic sustainability, we consider:

- The price and availability of the material, and how accessible it is for the desired end market

- The total cost of societal externalities, such as end of life waste management

- The cost of using this material vs. the value gained by using it long term

Yes, you have to. Sustainability is not optional. We make it easier.